BEWARE OF IMPOSTERS!

This is the official website of Zhang Xiangqian and his Unified Field Theory. At no time does Zhang Xiangqian authorize donation requests, fundraising campaigns, or solicitations outside of mainland China. All such requests and other websites are unauthorized.

Read the theory. Watch the experiment. Replicate the results.

Experiment Guide (Replication)

This page explains how to build the apparatus, run the test, and capture data so others can verify or refute the effect. If you improve the setup, please share your notes so we can update this guide.

Picture of dual-coil with 18 mm gap and test object

Picture of assembled apparatus with gap highlighted.

1) Purpose

This page explains how to build the apparatus, run the test, and capture data so others can verify or refute the effect. If you improve the setup, please share your notes so we can update this guide.

2) Safety first

Electrical & magnetic safety

-

Use a properly isolated power supply and keep hands/tools away from energized conductors.

-

Coils and cores can heat—monitor temperature; do not exceed component ratings.

-

Strong changing fields may affect medical implants or magnetic media—keep a safe distance.

-

Eye protection when cutting, soldering, or handling brittle ceramics.

-

Run in a clean, draft-free area away from fans/vents.

Proceed only if you are competent with basic lab and electrical safety.

3) Bill of materials (core + test objects)

Core apparatus

-

AC source / driver: AC 110–230 V, 60 Hz, up to 100 V / 20 A typical; max 230 V / 100 A / 70 °C rise.

-

Waveform: AC sine; on/off via AC contactor + pushbutton.

-

Phase: Single-phase drive.

-

Isolation: AC contactor (recommended).

-

Coils: 400 turns, Ø2 mm wire, wound on amorphous iron core.

-

Core: Non-crystalline iron (grade 1K107, μr ≥ 100,000, Bsat ≈ 1.25 T), toroid shape Ø130/190 × 30 mm.

-

Gap: 18 mm ± 1 mm.

-

DC resistance / inductance: not specified.

-

Mounting: Fixed with insulated ties; base: wood board.

-

Orientation: horizontal or vertical.

-

Sample holder: 18 mm wide insulating plate.

-

Tools: Non-metallic tweezers, calipers/ruler.

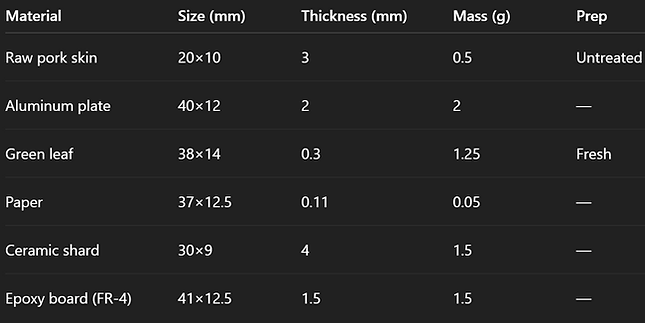

Six test objects (standardized size)

(Prepare samples to match these specs as closely as possible.)

4) Apparatus overview

Key dimensions to note

-

Gap: 18 ± 1 mm.

-

Coil inner/outer diameter: Ø130/190 mm; height 30 mm.

-

Turns: 400 turns per coil, winding direction arbitrary.

-

Core: amorphous iron 1K107, μr ≥ 100,000, Bsat = 1.25 T.

5) Build steps

-

Wind 400 turns of Ø2 mm wire; label coil leads.

-

Mount coils on core with 18 ± 1 mm gap; secure with insulation.

-

Fix base on wood board; minimize vibration.

-

Connect driver via AC contactor and isolated supply.

-

Verify idle operation at low voltage before adding test objects.

6) Operating procedure

-

Baseline: Record 10–20 s of empty gap at 60 Hz, low amplitude.

-

Place object: Use non-metal tweezers to position sample in gap.

-

Run: Apply AC signal (110 V, up to ~20 A). Energize coils for 1–3 seconds per run.

-

Optional sweep: Step frequency near 60 Hz ± Δf.

-

Cool-down: Allow coils to cool if temp > 70 °C.

Note: Use fine suspension threads to minimize torsional resistance. Measure magnetic flux in gap (0.1–0.3 T target).

7) Controls to rule out artifacts

-

Airflow: shield rig with wood enclosure.

-

Electrostatics: discharge samples / ground rig.

-

Magnetic pull: test dummy of equal mass & non-magnetic.

-

Heating/buoyancy: monitor coil & sample temp.

-

Vibration: ensure no contact between sample and coil; suspend carefully.

-

Blind placement (optional).

8) What to record (data & media)

Video

-

≥60 fps, preferably 2 cameras, ruler in frame.

-

Narrate: material, frequency, amplitude, gap, run ID.

Log fields

run_id, date_time, operator, material, mass_g, size_mm, gap_mm, frequency_Hz, drive_voltage, drive_current, coil_temp_C_start, coil_temp_C_end, ambient_temp_C, humidity_pct, observed_motion_notes, video_file

Optional: Oscilloscope screenshots, magnetic field readings, power consumption.

9) Success criteria / what to expect

-

Qualitative: Visible, repeatable motion in the gap under same settings.

-

Comparative: Different materials respond, controls do not.

-

Reproducible: Other teams can repeat with same parameters.

10) Troubleshooting

-

No motion: Recheck gap, coil turns, sweep freq, increase amplitude gradually.

-

Object flyaway: Lower voltage, use shallow holder.

-

Heating: Shorter duty, add cooldown.

-

Inconsistent: Shield airflow, use consistent sample sizes.

11) Submit a replication

12) Contact

For clarifications or collaboration:

📧 info@unifiedfield.info (general)

📧 press@unifiedfield.info (media)

Credit: Zhang Xiangqian – Gravity Experiment (张祥前 引力实验)